ResonantAcoustic® Mixing mixes virtually any combination of materials from bench development to production scale. RAM’s patented technology platform uses sound energy and large vertical displacement at 60 cycles per second to process powders, pastes, liquids, and combinations with breakthrough speed, quality, and repeatability. Match your industry’s requirements and materials to lean how RAM can deliver better performance for your applications.

Discover the principles that drive RAM performance. From rapid vertical displacement to low frequency sound energy, and the “secrets” of resonance, RAM harnesses and combines common phenomena to introduce and deliver ground-breaking results to virtually any industry.

Learn How RAM Mixes

It’s highly likely the answer is yes. It’s also likely that processing with Resodyn Acoustic Mixers will save you time, effort, and deliver higher quality results than traditional mixing methods. Sign up below for a FREE demonstration or a FREE mix test using your materials.

Notice: JavaScript is required for this content.

Pastes and viscous mixes are made up of solids in a liquid matrix. Less liquid in the matrix produces higher viscosity, into the hundreds of millions of centipoise – approaching what appears to be and behaves much like a solid. RAM mixes highly viscous materials at levels no traditional mechanical mixer can. Using sound energy, RAM mixers deliver wetting, incorporation, and widespread mixing rapidly and uniformly throughout the matrix.

RAM mixers accelerate these processes by inducing Faraday disturbances, or invasive “fingers” coupled with enveloping “cavities” at the boundary between materials of different densities. Progressing rapidly through wetting, incorporation, and mixing, RAM delivers highly homogeneous, higher viscosity results significantly faster than traditional technologies.

Traditional, blade and axis technologies can work through early stages of wetting and possibly incorporation, but often overheat or grind to a halt when mixing starts and the viscosity increases. Every highly viscous mixing process requires wetting, incorporation, and mixing phases. Without the mechanical limitations of axis/blade methods that require all materials to pass through a limited mixing zone, RAM technology performs all three steps simultaneously and consistently throughout the mixing vessel, reducing processing time by orders of magnitude.

RAM technology is a “non-contact” mixing method requiring no blades, propellers, or other engineered devices to cause mixing. This also means that the high shear traditionally associated with viscous materials can be eliminated, allowing delicate or hazardous materials to be processed rapidly without excessive heat build-up or physical shear stress.

The more viscous a material, the more difficult it is to mix traditionally. This means that consistent dispersion and distribution suffer at higher centipoise. These restrictive phenomena are completely avoided using RAM mixers at any scale. Sound energy wets, incorporates, and mixes materials rapidly, thoroughly and at levels of quality not previously possible. Over years of test data across numerous industrial installations, RAM devices have delivered exceptional results, well into the tens of millions of centipoise.

Every RAM device’s mixing parameter variables can be enhanced by combinations of vacuum, mixing payload temperature control, and other accessories. Viscous materials often mix more effectively at higher temperatures and under vacuum. RAM systems provide these functions before, during, and after actual mixing operations. This means that idle, degassing time, and failed batches due to the wrong temperature are eliminated.

RAM technology drives intense liquid to particle interaction at the wetting stage of viscous ingredient processing through Faraday Instabilities, [[link to that section elsewhere]] throughout the materials instantly and continuously. After incorporation, RAM’s sound energy enables mixing at high viscosities with sound energy. Without restrictions of mechanical mixing methods and the heat and sheer they generate, RAM allows highly viscous materials to be mixed at the densest levels.

To illustrate a heavily loaded polymer blend, two materials of very different particle sizes are blended with a polymer surrogate. This footage documents the nature of the material blending and integration into a heavily loaded (~85%) polymer based paste. The use of RAM™ technology is ideally suited for loading of solids into polymers and mixing to a high rate of dispersion and consistent viscosity throughout the blend.

Link to relevant content on our patent list page.

Links to selected related articles – off-site links

We love challenges! Get in touch with us for a free mix test or an onsite demo.

Contact Us

Liquid mixing and processing is often more complex than they seem on first inspection. Varying properties like viscosity density, miscibility, solubility, behavior at temperature, phase change, and many others complicate mixing and processing of liquids. RAM technology overcomes these challenges unlike any other technology. Utilizing the ResonantAcoustic® Mixing (RAM) technology platform common to all devices, RAM’s sound energy induces Faraday disturbances, or invasive “fingers” coupled with enveloping “cavities” at the boundary between liquids of differing characteristics.

Traditional mixing methods process liquids by creating vortices at the ends of blades, propellers or other engineered devices and accessories. This localization of the mixing function requires that all the liquid to be processed must be repeatedly brought “to the mix” and driven through the small mixing zones to achieve mixedness. RAM technology mixes everywhere immediately and continuously, bringing the “mix to the material.” The result is rapid, effective, and efficient mixing and processing of virtually any liquid with any other liquid or liquids. Blending is fast and complete. Emulsions are conformant and stable. Minor ingredients are thoroughly and consistently dispersed.

RAM mixing processes do not require the “right” sequence of ingredient additions. RAM technology mixes throughout the entire vessel, immediately and continuously. Direct, multiple ingredient processing eliminates ingredient addition time, ingredient addition error, and virtually eliminates individual ingredient vessel clean-up.

The superior result of RAM mixing contributes to better suspension and longer term stability of many liquid mixes

RAM technology drives intense liquid to liquid boundary interaction through Faraday Instabilities, [[link to that section elsewhere]] throughout the materials instantly and continuously. RAM delivers rapid, thorough mixing with excellent suspension stability and improved product shelf life.

Many polymer based processing applications require additional ingredients for performance or coloration. To illustrate RAM’s ability to quickly and thoroughly mix ingredients of different characteristics, 2.5 grams of food coloring was blended with 235 grams of a polymer surrogate. The final mixture shows the liquid fully dispersed within the polymer due to the unique and effective mixing action captured in the high speed footage.

Link to relevant content on our patent list page.

Links to selected related articles – off-site links

We love challenges! Get in touch with us for a free mix test or an onsite demo.

Contact Us

Powders of nearly any size, material characteristic, or morphology are rapidly and thoroughly mixed using RAM technology. Additionally, RAM processing is frequently orders of magnitude faster than traditional technologies.

The RAM platforms’s rapid, 60Hz motion causes each particle to randomly collide with adjacent particles, diverting their paths, colliding and re-colliding with other particles behaving in equally chaotic fashion.

Chaotic particle collision and large scale vapor migration speed dispersion and ultra-high uniformity.

Static and other physical forces combine to thoroughly coat particles, one material on another, layer upon layer.

Agglomerated materials are separated into uniform particles that are segregated rapidly with sieving attachments.

With the selection and addition of appropriate milling media, RAM can also be used to reduce particle size or change particle morphology.

RAM technology can be used to separate mixed particles of varying sizes using common sieves. Low frequency operation speeds separation and flow-through of particles to cleanly and thoroughly segregate particles.

RAM technology drives particle to particle collision and generates large-scale vapor migration, vastly improving both modes of powder mixing.

ResonantAcoustic® Mixing

Traditional tumbling methods use a single g of gravity to circulate mixing powders in small scale particle cascading

Using less than 30 rpm, traditional methods must avoid centripetal motion to keep particles involved in mixing

RAM generates up to 100 g of acceleration driving chaotic motion through the mixing media

RAM uses intense chaotic motion without any centripetal forces or de-mixing phenomena

Videos

Case Studies

White Papers

Patents

Articles

Dissimilar Powder Mixing

Dry ingredients can be difficult to thoroughly and consistently mix, particularly when the particles are of different sizes and characteristics. To illustrate effective and rapid mixing, 10 grams of fumed silica is blended with 100 grams of sand. Completed specimens exhibit no airborne fumed silica, demonstrating uniform blending at an order of magnitude difference in particle size.

Milling and Nano Coating

Coating larger particles with smaller ones is a common processing application, and milling is often a part of the same process. In this video, agglomerated carbon black particles are simultaneously milled to nano size particles that coat the plastic pellets completely in just a few seconds. The high speed video clearly illustrates the dispersion of carbon black particles, their de-agglomeration, and progressive and comprehensive coating of the plastic pellets.

White Paper 1 – Brief description of this paper.

Poster 1 – Brief description of this poster.

White Paper 2 – Brief description of this paper.

White Paper 2 – Brief description of this paper.

Poster 2 – Brief description of this case poster.

White Paper 3 – Brief description of this paper.

Etc.

Link to relevant content on our patent list page.

Links to selected related articles – off-site links

We love challenges! Get in touch with us for a free mix test or an onsite demo.

Viscous slurries and pastes are made up of solids in a liquid matrix, requiring multi-stage mixing of the materials. RAM mixers accelerate these processes by inducing Faraday Disturbances, or invasive “fingers” coupled with enveloping “cavities” at the boundary between materials of different densities.

Progressing rapidly through wetting, incorporation, and mixing, RAM delivers highly homogeneous, higher viscosity results significantly faster than traditional technologies.

Every liquid-solid mixing process requires wetting, incorporation, and finally mixing processes. Without the necessity of all materials to pass through a limited mixing zone using propellers, RAM technology performs all three steps simultaneously and consistently throughout the mixing vessel, reducing processing time by orders of magnitude.

RAM mixing processes do not require the “right” sequence of ingredient additions. RAM technology mixes throughout the entire vessel, immediately and continuously. Direct, multiple ingredient processing eliminates ingredient addition time, chance for addition error, and virtually eliminates individual ingredient vessel clean-up.

The superior result of RAM mixing contributes to better suspension and longer term stability of slurries. Solid particles that tend to agglomerate and fall out of suspension are better separated and thus stay in suspension for longer periods, in some cases permanently.

Named after Michael Faraday, a 19th century scientist, Faraday Instabilities are nonlinear waves that appear on liquids due to the high amplitude, periodic driving force. Under the proper conditions, the flat surface of the liquid becomes unstable. RAM technology is particularly effective at inducing these instabilities and is the first technology to make practical use of the phenomenon.

In the high-speed video below, instabilities can be seen both above and below the clear liquid surface as spikes, or fingers above the surface as well as cavities below. Vast increases in the surface area of the material boundary facilitates and accelerates mixing of the materials.

When occurring in a liquid–solid mixing environment, the same phenomenon occurs, though largely hidden from view, resulting in rapid, thoroughly mixed and dispersed solids in the liquid matrix. In this high speed video, orange chalk is incorporated rapidly into corn syrup.

RAM technology drives intense liquid to particle interaction through Faraday Instabilities throughout the materials instantly and continuously. ResonantAcoustic® Mixing delivers rapid, thorough mixing with excellent suspension stability and improved product shelf life.

Many polymer-based materials require the addition of dry or powder materials for specific performance characteristics or coloration. To illustrate dry powder incorporation in a viscous liquid, a small amount of dry ingredient is rapidly blended with a viscous liquid. This footage of mixing phenomena reveals how the thoroughly blended and uniform mixture is achieved in a very short mixing time.

Link to relevant content on our patent list page.

Links to selected related articles – off-site links

We love challenges! Get in touch with us for a free mix test or an onsite demo.

Contact Us

Learn what is industrial engineering, design and management when you compare courses and degree programs, both campus on online, at schools near you. Start your program today!

Use this static Page to test the Theme’s handling of the Blog Posts Index page. If the site is set to display a static Page on the Front Page, and this Page is set to display the Blog Posts Index, then this text should not appear.

Sr. Mechanical Engineer

Butte, MT | Full-time

Director of Operations

Butte, MT | Full-time

Outside Technical Sales Engineer

Butte, MT | Full-time

Sr.Chemical Engineer

Butte, MT | Full-time

Senior Chemist (Process Development)

Butte, MT | Full-time

Resodyn loves Butte, Montana and we think you will too. Surrounded by incredible outdoor opportunities, packed with history, and populated by the friendliest people you’ll ever meet, Butte also boasts a remarkably low cost of living.

Click one of the links below to learn more about our historic city, nestled in the beautiful Rocky Mountains of Southwest Montana.

The Resodyn™ Acoustic Mixers vision is to enable our customers to achieve a level of product quality and manufacturing competitiveness never before thought possible.

Resodyn Acoustic Mixers provide advanced solutions for a broad range of industrial mixing and processing challenges.

Combine all types of hard-to-mix materials:

The ResonantAcoustic® mixing process can be used for solid-solid, solid-liquid, and liquid-gas systems without the use of impellers. This advanced, highly effective mixing process is well suited for dispersing fine materials, including nano-materials, throughout any mix matrix.

Resodyn Corporate HQ in the historic Hennessy Building.

Please don’t hesitate to call!

Email us your questions any time.

Mon – Fri: 8:00 – 17:00 Mountain (UTC-07:00)

130 North Main Street, Suite 630

Butte, Montana, USA 59701

We’re excited to hear from you.

Notice: JavaScript is required for this content.

See how RAM delivers results with your materials.

Tel: 4064975333

dwynn@example.com

Proin gravida nibh vel velit auctor aliquet. Aenean sollicitudin, lorem quis bibendum auctor, nisi elit consequat ipsum, nec sagittis sem nibh id elit. Duis sed odio sit amet nibh vulputate cursus a sit amet mauris. Morbi accumsan ipsum velit. Nam nec tellus a odio tincidunt auctor a ornare odio. Sed non mauris vitae erat consequat auctor eu in elit.

Tel: 4064975333

jake@example.com

Proin gravida nibh vel velit auctor aliquet. Aenean sollicitudin, lorem quis bibendum auctor, nisi elit consequat ipsum, nec sagittis sem nibh id elit. Duis sed odio sit amet nibh vulputate cursus a sit amet mauris. Morbi accumsan ipsum velit. Nam nec tellus a odio tincidunt auctor a ornare odio. Sed non mauris vitae erat consequat auctor eu in elit.

Tel: 4064975333

john@example.com

Proin gravida nibh vel velit auctor aliquet. Aenean sollicitudin, lorem quis bibendum auctor, nisi elit consequat ipsum, nec sagittis sem nibh id elit. Duis sed odio sit amet nibh vulputate cursus a sit amet mauris. Morbi accumsan ipsum velit. Nam nec tellus a odio tincidunt auctor a ornare odio. Sed non mauris vitae erat consequat auctor eu in elit.

Westcott Venture Park, Westcott

Aylesbury, Buckinghamshire

HP18 0XB

United Kingdom

Telephone: +44-01296-651-732

Email: info@resodynmixers.com

Web: https://resodynmixers.com

#E – 701, Smart Valley

Songdo miraero 30

Yeonsu-gu, INCHEON

Republic of Korea, 21990

Telephone: +82-32-831-2611

Email: info@yes-solutions.ko.kr

Web: http://www.yes-solutions.co.kr

Sumitomo Irifune Bldg 2F

1-1 Irifune 2-chome

Chuo-ku, Tokyo 104-0042

Japan

Telephone: +81-3-5542-6754

E-mail : ![]()

Web: https://www.altech.co.jp

130 North Main Street

Suite 630

Butte, Montana 59701

USA

Telephone: +1-406-497-5333

Email: info@resodynmixers.com

Web: https://resodynmixers.com

Please don’t hesitate to call!

Email us your questions any time.

Please fill out the form below to submit a support request. You will receive a reply within 24-hours Monday-Friday.

Notice: JavaScript is required for this content.

Resodyn carries a wide selection of replacement parts, vessels, and supplies for Resodyn Acoustic Mixers. Please fill out the form below for prompt service. You may also call us at +1-406-497-5333 or email support@resodyn.com.

Notice: JavaScript is required for this content.

Test Test Test

ResonantAcoustic® Mixing mixes virtually any combination of materials from bench to production. RAM’s patented technology platform uses sound energy, large vertical displacement at 60 cycles per second to process powders, pastes, liquids, and combinations with breakthrough speed, quality, and repeatability. Follow the link below that is closest to your material to see what RAM can do for you, or click here to see all RAM applications.

Discover the principles that drive RAM performance. From rapid vertical displacement to low frequency sound energy, and the “secrets” of resonance, RAM harnesses and combines common phenomena to introduce and deliver ground-breaking results to virtually any industry.

Learn How RAM Mixes

From the world’s top pharmaceutical companies, to international manufacturers, global tech giants, and nearly every U.S. National Laboratory, 800+ Resodyn Acoustic Mixer installations encircle the globe on a single, powerful technology platform.

Manufactured in the U.S., Resodyn Acoustic Mixers ships products to more than 30 countries. Whether developing new materials in the laboratory or running full-scale industrial production, RAM systems are available in configurations to fit your application.

RAM sales professionals deliver high value, on-site application presentations, product technology demonstrations, and even mixing tests using your own materials, without cost to you. Contact us today or specify when and how to contact you to discuss your requirements.

Let’s Talk vamtam-theme-circle-post

vamtam-theme-circle-post

vamtam-theme-circle-post

vamtam-theme-circle-post

vamtam-theme-circle-post

vamtam-theme-circle-post

vamtam-theme-circle-post

vamtam-theme-circle-post

ResonantAcoustic® Mixing will change the way you think about mixing and processing. See for yourself with an on-site Mixer demonstration at your facility, using your materials, or we can mix-test your materials for free.

Sign up below to qualify.

Notice: JavaScript is required for this content.

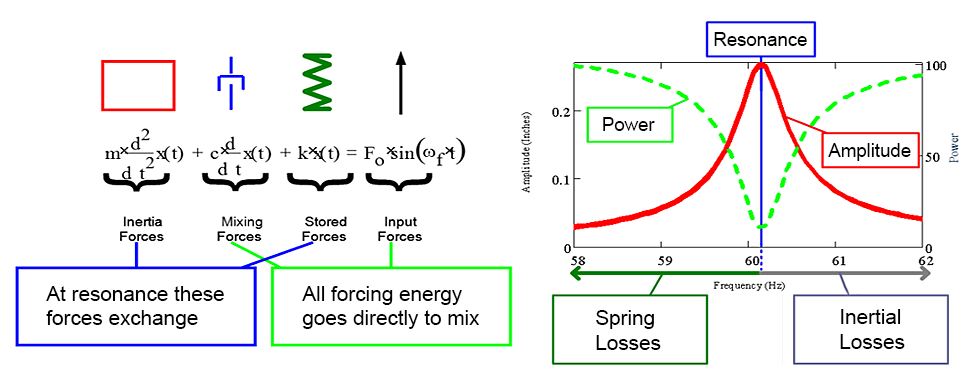

An opera singer can shatter a champagne glass using her voice at the same resonant frequency as the fluted glass. Suspension bridges can be swayed wildly and destroyed under influence of winds that swing the bridge at its resonant frequency.

The resonant condition also requires very little energy to be maintained, making ResonantAcoustic® Mixers very efficient to operate.

First vertical motion at 60 times per second with a maximum amplitude (peak to trough) of 0.55 inches. This is considered a fairly low frequency with a high displacement, or RAM’s “sweet spot.”

Second, the acoustic effects of the mixers’ transducers, or energy transferring surfaces. The combination of these forces can cause several beneficial effects in the material to be mixed or processed.

The effects to the materials include

All while eliminating cycle-based demixing.